Predictive maintenance techniques are designed to help determine the condition of in-service equipment in order to estimate when maintenance should be performed. This approach promises cost saving over routine or time-based preventive maintenance, because tasks are performed only when warranted. The main promise of predictive maintenance is to allow convenient scheduling of corrective maintenance, and to prevent unexpected equipment failures.

The key is "the right infor quipment lifetime, increased plant safety, fewer accidents with negative impact on environment, and optimized spare parts handling.

Predictive maintenance differs from preventive maintenance because it relies on the actual condition of equipment, rather than average or expected life statistics, to predict when maintenance will be required.

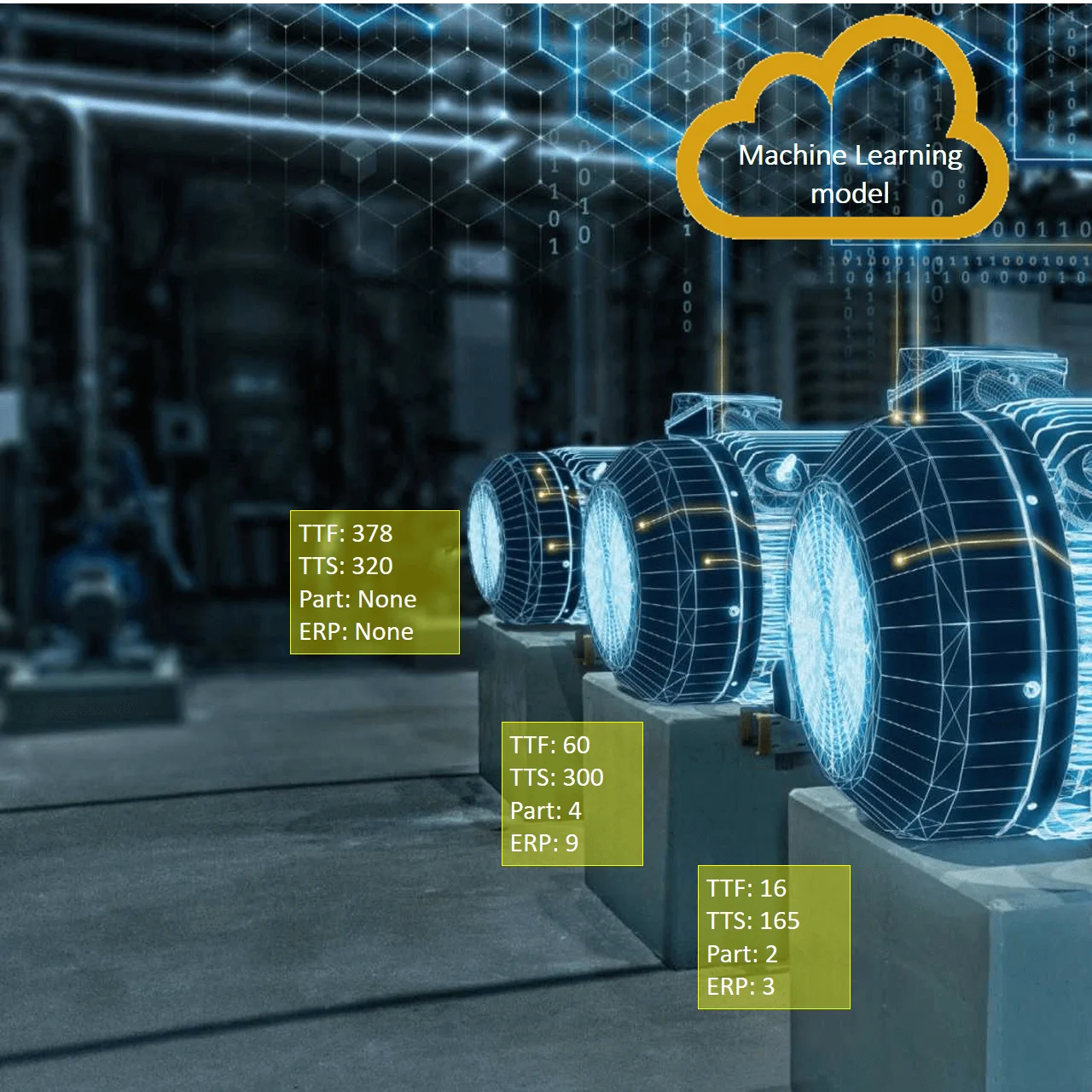

ZeoAnalyzer is successfully deployed in manufacture unit, which is analytics and reporting tool which captures the data from the machine using IoT sensors form where data send to cloud. ZeoAnalyzer performs stream analytics,send report and alerts to maintenance manager regarding time to failure, regular maintenance parts and simultaneously communicate with ERP system for spare part details.

By doing this zeoanalyzer reduces the maintenance cost and increase productivity of the machines